Gear Pumps

When you need to transport fluids using a system based on the action of a positive displacement pump, often what’s called for is a gear pump.

With a gear pump, you are able to move fluid around by enclosing a specific amount of the liquid on a repeating basis, with gears or cogs that interlock with one another. The fluid moves via cyclic pumping, so you have a flow that is free of pulsations. As a result, the fluid moves in proportion to how fast the gears are rotating.

What Are Gear Pumps Used For?

Typically you will find gear pumps used by businesses that need to transport fluids of high viscosity. This is often the case in companies dealing with chemicals.

With a gear pump, you actually have two gears that are set apart on the pump’s intake. A partial vacuum occurs, generating the suction forces that move fluids into the pump, even if they are quite thick.

At this point, the gears move the fluid through and out of the pump. It’s a simple matter of the gears’ rotational movement displacing these fluids. And you’ll be glad to know that the way these gear pumps are designed and built, the fluid is only permitted to flow from the intake to the outtake area of the pump.

What Are the Different Types of Gear Pumps?

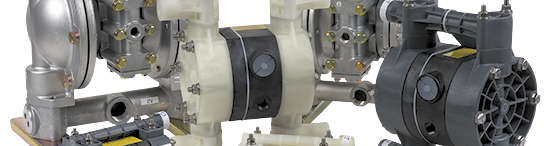

Gear pumps are available in two types: internal and external.

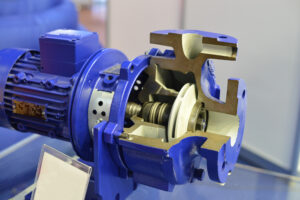

Internal Gear Pumps: With an internal gear pump, it functions the same way as an external model, except that the two gears that interlock are sized differently, so one can rotate within the other one.

The rotor is the larger internal gear with teeth that project inward. At the center of the rotor is a smaller external gear called the idler, which features an off-center mount. So, the teeth of the gear engage at a single point. An internal gear pump keeps its idler in the correct position with a bushing and pinion connected to the casing of the pump.

External Gear Pumps: These employ dual interlocking gears connected to their own shafts, and they are identical.

A motor drives one shaft, causing the other gear, the idler, to move in turn. But some configurations have each shaft driven by a motor. As you’d expect, there are bearings to support the shafts.

Gear Pump Applications

Gear pumps are suitable for a range of applications, and figure heavily in petrochemical companies for diesel, lube and crude oil. Organizations will use gear pumps to move chemicals that require special handling, such as acids, plastics and mixed chemicals.

You can also find gear pumps used in the movement of paint, resins, adhesive products and inks.

They are also used to great effect by food manufacturers dealing with thick fluids such as vegetable fats, chocolate, and molasses.

We’re Here to Help You Source the Right Gear Pumps for Your Applications

For more than 50 years, the team at Master Pumps & Power has been helping customers obtain the specific pumps they require for the job at hand.

Whether you are a startup business or have been in the industry for some time now, you should know that we can deliver a customized solution or help guide you to find a standard configuration for the gear pumps you require. To consult with our pump experts, please get in touch with us at your earliest convenience.